ALL ABOUT MURANO GLASS

This section gives you some background on where Murano is and how the various techniques are used to develop these exquisite works of art.

History and Location

Murano is a group of islands near Venice, linked by a series of interconnecting bridges. It lies about a mile north of Venice and is famous for its glass making, particularly lampworking. Murano was settled by the Romans, then from the sixth century by people from Altino and Oderzo. At first, the island prospered as a fishing port and through production of salt. It was also a centre for trade.

Murano is a group of islands near Venice, linked by a series of interconnecting bridges. It lies about a mile north of Venice and is famous for its glass making, particularly lampworking. Murano was settled by the Romans, then from the sixth century by people from Altino and Oderzo. At first, the island prospered as a fishing port and through production of salt. It was also a centre for trade.

In 1291, all the glassmakers in Venice were forced to move to Murano due to the risk of fires. In the following century, exports began, and the island became famous, initially for glass beads and mirrors.

Glass Making Techniques

1. Murrina Technique

There are three main glassmaking techniques used in the manufacture of our jewellery. All of these are done by hand in old traditional ways, resulting in jewellery items which are works of art, with no two alike.

The first, and most laborious and time consuming, is the Murrina technique.

First there is the making of the Murrina rods. The molding of the rods begins by taking a small amount of Murano glass at the end of

First there is the making of the Murrina rods. The molding of the rods begins by taking a small amount of Murano glass at the end of  a 1.5m pole. This is dipped into various pots of molten glass so that the mass increases and becomes made up of multi-coloured layers. This mass is then squeezed into star- and flower- shaped molds to give it its final form. A last layer of glass keeps the cylindrical form in shape. Then another pole is attached to the end of the mass.

a 1.5m pole. This is dipped into various pots of molten glass so that the mass increases and becomes made up of multi-coloured layers. This mass is then squeezed into star- and flower- shaped molds to give it its final form. A last layer of glass keeps the cylindrical form in shape. Then another pole is attached to the end of the mass.

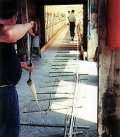

Venetian glassmakers walk in opposite directions, pulling out the Murano glass into a long fine rod, using only their eyes and experience to guage the right diameter. The rods are then cut into tiny Millefiori beads.

These beads are then placed into a copper frame to make a mosaic. The composition of different shapes and colours is done entirely

patterns and designs to put together the vast range of colours that are the feature of Murano glass.

patterns and designs to put together the vast range of colours that are the feature of Murano glass.

After this the frames are put into the glass oven in special containers and left overnight, where the glass begins to melt, increasing its thickness. The glass is then ground and cleaned by hand, piece by piece, and this grinding and cleaning process takes approximately one hour per piece! Then the glass can be used to make the beautiful jewellery we enjoy.

2. Lampwork Technique

The second process is the Lampwork technique. This is done by melting different types of glass together, enabling the continuous

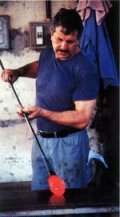

The second process is the Lampwork technique. This is done by melting different types of glass together, enabling the continuous  creation of new shapes and colour combinations. To work the glass, the master glass-maker uses a gas-flame which is lit all day and reaches very high temperatures. He or she uses a transparent or coloured glass rod and blends in other materials such as glass, gold, silver and other precious minerals. This technique is the most difficult and has been handed down from father to son over hundreds of years. It requires a great deal of patience, imagination and precision.

creation of new shapes and colour combinations. To work the glass, the master glass-maker uses a gas-flame which is lit all day and reaches very high temperatures. He or she uses a transparent or coloured glass rod and blends in other materials such as glass, gold, silver and other precious minerals. This technique is the most difficult and has been handed down from father to son over hundreds of years. It requires a great deal of patience, imagination and precision.

3. Vietro in Piastra Technique

The third process is the Vietro in Piastra or Glass Slab technique. This is the most modern. After putting a whole slab of Murano glass on a table, different loose materials such as Murrina glass, gold and silver foil and small pieces of coloured glass are sprinkled over it. As with the other techniques, much patience and imagination is

The third process is the Vietro in Piastra or Glass Slab technique. This is the most modern. After putting a whole slab of Murano glass on a table, different loose materials such as Murrina glass, gold and silver foil and small pieces of coloured glass are sprinkled over it. As with the other techniques, much patience and imagination is required. After this, another slab of Murano glass of a different colour is placed on top, like a sandwich, and the whole is baked overnight in a large oven. Then the glass is ready to be cut into different molds and handmade objects.

required. After this, another slab of Murano glass of a different colour is placed on top, like a sandwich, and the whole is baked overnight in a large oven. Then the glass is ready to be cut into different molds and handmade objects.

CUSTOMER SERVICE |

|

|